Resources Technology and Critical Minerals Trailblazer projects

Project funds are received from UQ, Trailblazer and industry to advance innovative research ideas, progress technology readiness and support commercialisation pathways.

Current projects

Click a heading below to view each project's aims and objectives, key researchers, industry partners, and links to further information.

Key researchers

Industry partner

- Evolution Mining

Aims and objectives

The aim is to develop a novel time and cost-effective process for scaling up the rehabilitation of tailings and mine waste, using a combination of a novel hybrid soil cover system and resilient species of plants referred to herein as ‘superplants.’ All mine residue, across the globe, requires the reestablishment of soil and vegetation covers. Some sites have adopted a preferred cover design based on models that are not always validated by field trials. Our scale-up approach aims to minimise the risk of cover failures by incorporating superplants into a live cover system, therefore de-risking the progressive rehabilitation and closure plans.

Key researchers

Industry partner

- JK Tech

Aims and objectives

This project commercialises UQ’s small-scale (~200 kg/h) processing circuit, enabling mining companies to prototype innovative flowsheets for new economy minerals. It supports low-energy, low-emission extraction methods and helps de-risk processes critical to the energy transition, filling a gap in industry testing capabilities. As rising metal demand and declining grades drive up energy use, emissions, and tailings, this innovation supports profitability while enhancing ESG performance. Mining companies can test flowsheets faster and earlier in project development, reducing processing footprints and improving sustainability.

Key researchers

- Associate Professor James Vaughan

- Dr Julius Motuzas

Aims and objectives

This project aims to demonstrate novel percrystallisation technology in a scaled-up pilot reactor which can be operated continuously for extended periods of time, derisking technology commercialisation. The demonstration of percrystallisation is a step towards commercialisation of this new processing technology which is significantly more productive than conventional evaporative crystallisation. There are exciting opportunities to deploy the technology for zero-liquid discharge applications and in production of metal salts, relevant to the processing of critical minerals into valuable metal products.

Key researchers

Industry partners

- Gallium Qld

- K2HPA Pty Ltd

Aims and objectives

This project is testing a new method of making high purity alumina (needed in advanced electronics and batteries) using cheap and abundant clay minerals rather than rarer aluminium ores. The project aims to develop the means to produce HPA from abundant and easily mined kaolin as opposed to rarer and more valuable bauxite.

Key researchers

- Associate Professor James Vaughan

- Dr Hong Peng

- James Gudgeon

- Albert Mueller

Industry partner

- QEM

Aims and objectives

A process for recycling vanadium from spent sulphuric acid plant catalyst was developed and piloted at laboratory scale. 100g of high purity V205 was produced from the spent catalyst. The next stage of the project will be to further optimise the process, test different catalyst feed, and demonstrate all steps at a larger scale. This will inform technical-economic analysis and design of a pilot plant. With Australia categorising Vanadium as a Critical Mineral and currently not having any domestic production yet, this project could be the first to domestically produce Vanadium until the larger mines are in production. This early source of Vanadium would help establish a battery manufacturing industry and attract foreign companies to bring their technology to Australia.

Key researchers

Industry partner

- Lanxess

Aims and objectives

The project objective is to develop process for nickel sulfate solution purification using Lanxess adsorbent material. Granular adsorbents are marketed by technology supplying companies such as Lanxess. These functional materials are of increasing importance in hydrometallurgical solution purification, enabling high purity products to be recovered. In this project, experimental reactors will be constructed and assembled to be able to test adsorbent performance in batch and continuous process mode. The performance of the materials will be evaluated for multiple applications (e.g. preparation of solutions for high purity nickel sulfate, nickel hydroxide and zeolite product recovery).

Preliminary technical economic analysis suggests that adsorption of Si using granular adsorbent is much less expensive than evaporative precipitation of silicates, provided the adsorbent can be regenerated and reused. This technology will address a challenge in creating high purity nickel sulfate and nickel hydroxide from silicate containing ore feed or from intermediate products precipitated with silicate (Mixed Ni-Co Hydroxide Precipitated with Naturally Sourced MgO).

Key researchers

Industry partners

- Physical Electronics

Aims and objectives

This project aims to advance ToF-SIMS surface analysis for mineral processing by improving sample preparation, data acquisition, and spectral analysis, and validating its application through case studies to support industry adoption.

Key researchers

Xiaodong Ma

Industry partners

Rio Tinto

Aims and objectives

This project aims to establish an advanced electric ironmaking laboratory (EIL) to support the development of the cutting-edge ironmaking process, the hydrogen Pilbara DRI and Electric Smelting Furnace (ESF) route. The EIL will provide key fundamental inputs required to design and prove the yet-commercialised ESF. This will assist to mitigate risks during pilot design/operation and scaling to a commercial ESF, and identify and remove any constraints when using Australian Pilbara iron ores. The EIL will develop a fast DRI-ESF testing methodology that is applicable to the operation of the ESF from pilot plant to full-scale process.

Key researchers

Bin LUO

Industry partners

Livium Ltd, VSPC PTY LTD

Aims and objectives

This project aims to develop, design, and produce lithium iron phosphate (LFP) and lithium manganese iron phosphate (LMFP) materials for next-generation lithium-ion batteries (LIBs) with superior energy density, reduced cost, and extended cycle life. Livium Ltd and its subsidiary VSPC PTY LTD will share their experience and facilities for cathode material development and pilot-scale production. The expected outcome of this project includes commercial-scale production of high-energy-density and low-cost cathode materials for LIBs, together with related synthesis technologies and production protocols. These outcomes will not only contribute to cheaper and more efficient battery technology for Australia, but also further strengthen and lift the position of UQ in industry engagement and commercialisation. In addition, Livium Ltd plans to explore the possibilities of exploiting their existing proprietary production processes to develop new cathode products. This project will also allow UQ and Livium Ltd to collaborate in investigating the potential for these products to be made at lab scale, tested for performance against industry standards, and assessed for performance and suitability. Ultimately the aim will be to identify the best new product/s suitable for manufacture and for a new commercial product line for Livium Ltd.

Key researchers

Eric Owusu Ansah

Industry partners

Northparkes Operations

Aims and objectives:

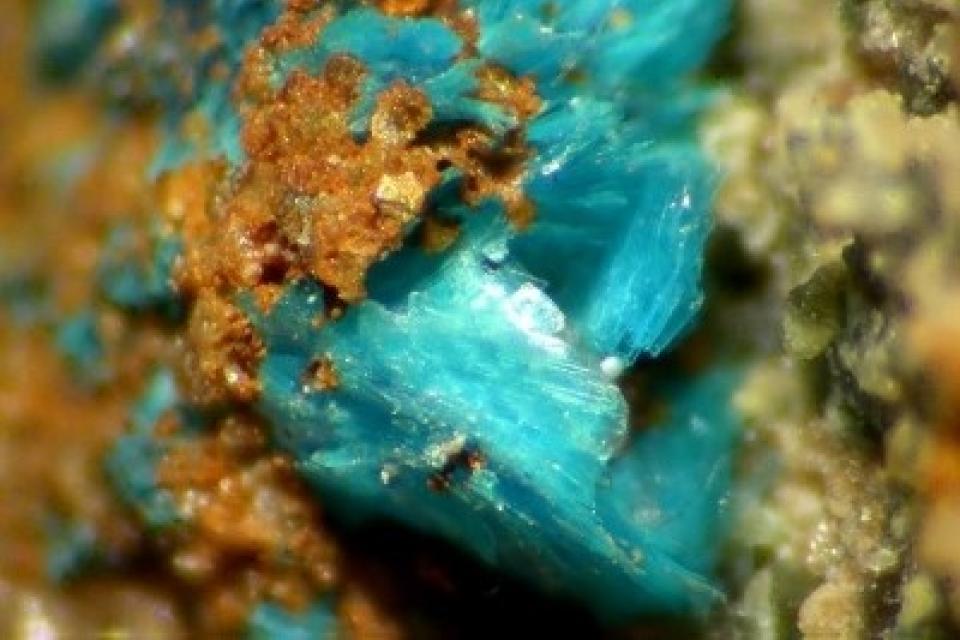

Trial protonated brine leaching to extract copper and other metals from low-grade oxide ores, aiming to reduce environmental impact and unlock stockpiled resources unamenable to current processing flowsheet.

Learn more about the project

Key researchers

Peter Erskine

Industry partners

Botanickel

Aims and objectives

Using multispectral drone imagery to optimise nickel phytomining with hyperaccumulator plants, developing criteria for global deployment and validating through field trials.

Key researchers

Robin Burgess-Limerick

Industry partners

BHP

Aims and objectives

Develop software to support human-centred design in mining automation, guiding integration of autonomous systems and improving safety and operational readiness.

Key researchers

Christian Antonio

Industry partners

Sedgman, JKTech & Newmont (Newcrest)

Aims and objectives

Scale up and commercialise the Grizzly-Electrode HVP system to improve ore preconcentration, reduce energy use, and enhance mineral liberation through pilot demonstrations and techno-economic validation.

Key researchers

Christian Antonio

Industry partners

BHP

Aims and objectives

Design and demonstrate a continuous HVP processing unit to validate the Grizzly-Electrode system in operational environments, supporting commercialisation for large-scale mineral processing.

Key researchers

Christian Antonio

Industry partners

Rio Tinto

Aims and objectives

Develop infrastructure and engineering design for pilot-scale HVP systems, enabling deployment in mining operations and supporting broader industry adoption of selective ore processing

Key researchers

Industry partners

- Banksia Minerals Processing

Aims and objectives:

Develop and scale a modular leach-electrowinning process for copper production at mine sites, reducing emissions and enabling recovery of multiple metals.